Sodium Silicate

Application field of sodium silicate, by taking advantage of its unique properties, has achieved epoch-making development such as silica gel, precipitated silica, colloidal silica, civil engineering, papermaking, adhesives, casting, etc.

Product Usage

-

- Civil engineering

- Materials for soil improvement, shield tunnel constructions

-

- Construction

- Materials for concrete surface treatment, refractories, geopolymers

-

- Anhydrous silicate

- Raw materials for silica gel, precipitated silica, colloidal silica, etc.

-

- Soap and detergent

- Builder and additives

-

- Casting

- Inorganic binder for casting sand

-

- Paper and pulp

- Suppression of self-degradation of bleach and promotion of free paper fiber

-

- Synthetic zeolite

- Raw materials for various zeolites such as adsorbed separators, ion exchange materials, catalysts, etc.

-

- Welding

- Welding flux binding agent

-

- Ceramic

- Binders, dispersant and peptizer for cray

-

- Adhesive

- Adhesives for inorganic fibers, building materials and molds, also for coating agents and sealing materials

-

- Textile

- Suppression of self-degradation of bleach and for fire-proofing processing

-

- Water treatment

- Flossant adulants for the removal of trace impurities

-

- Other uses

- Raw materials for various silicate, sodium meta and orthosilicate for degreasing agent, coating agent for titanium oxide, and sodium silicate powder for ceramics and detergent

Fuji Chemical specifications of sodium silicate

| No.1 | No.2 | No.3 | No.4 | No.5 | |

|---|---|---|---|---|---|

| Na2O% | 15.0 - 16.0 | 11.3 - 12.3 | 9.0 - 10.0 | 7.2 - 8.2 | 6.5 - 7.5 |

| SiO2% | 31.0 - 33.0 | 27.5 - 29.5 | 28.0 - 30.0 | 24.0 - 26.0 | 25.0 - 27.0 |

| Specific Gravity (20℃) | 1.56 - 1.59 | 1.435 - 1.465 | 1.39 - 1.42 | 1.31 - 1.34 | 1.31 - 1.33 |

| Fe% | < 0.02 | < 0.02 | < 0.02 | < 0.02 | < 0.02 |

| Insolubility% | < 0.2 | < 0.2 | < 0.2 | < 0.2 | < 0.2 |

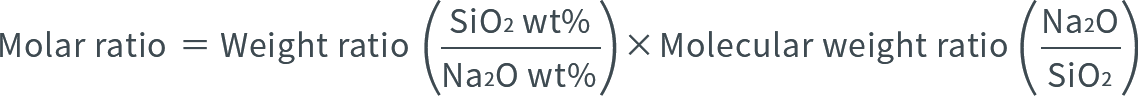

In most cases, the sodium silicate product with appropriate molar ratio is selected depending on the application.

In production, from sodium silicate No.3, which is most common grade, No.1 and No.2 are processed by adding caustic soda. No.4 and No.5, on the other, are manufactured by adding silica to No.3.